Manufacturing Software Development Services

Smarter factories, stronger growth

Cut costs, boost sales, and scale effortlessly with Industry Tech – enhancing efficiency, automation, and resilience in modern manufacturing.

Consult your idea

50%

cut order-to-production time with our tailored solutions

+30k

custom-configured products managed daily with our seamless solutions

0.5s

to synchronize order data between all legacy systems and the sales platform

Strategic benefits for lasting success

Increased operational efficiency

Connect the dots with your data and make production run like clockwork. AI-driven automation and real-time data synchronization keep production, warehouses, and logistics running smoothly, without bottlenecks. Less downtime, less CO2, smarter resource use, and seamless coordination – with our solutions, every process stays on track and optimized.

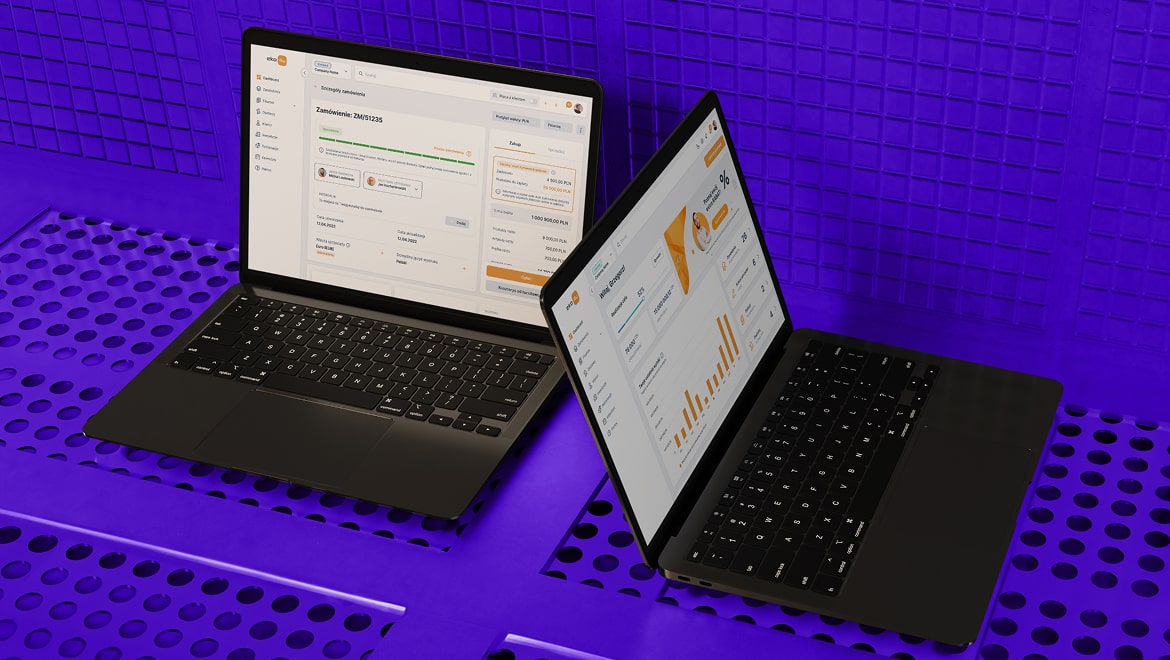

Reduced operational costs

No more data silos or delays. Improve production planning, optimize inventory, and boost operational efficiency with real-time data at your fingertips. Get instant access to critical information from both legacy and modern systems. With AI-powered insights, your team makes smarter decisions—faster.

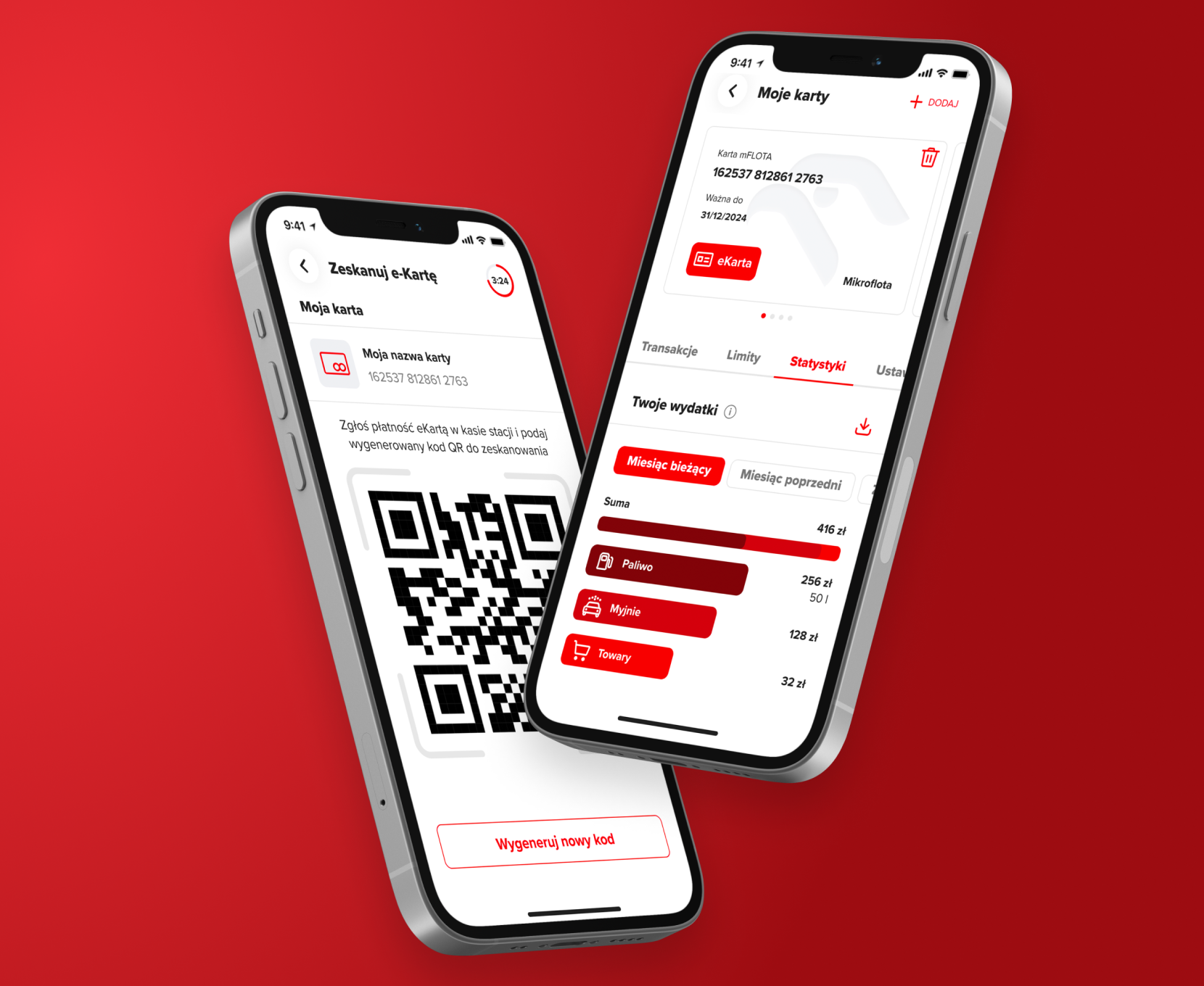

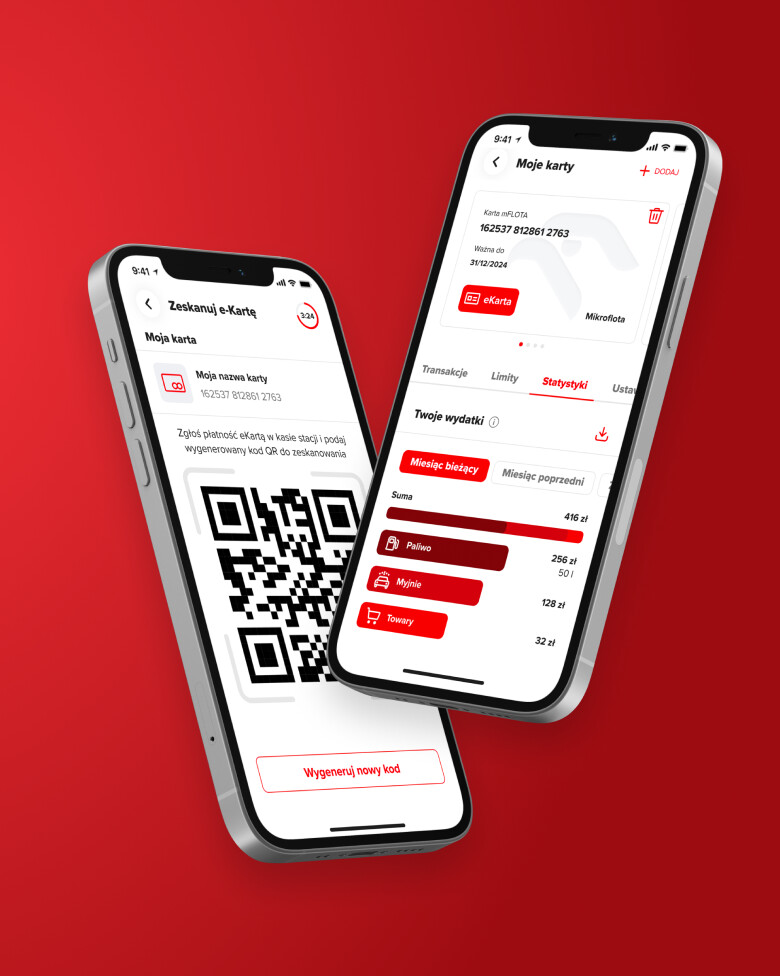

Enhanced customer satisfaction and sales performance

Long wait times often mean missed opportunities. Our AI-powered chatbots and omni-channel sales platforms deliver instant responses, speed up order processing, and keep customers informed. The result? Stronger trust, higher retention, and more conversions across B2B and B2B2C sales channels.

Faster decision-making with real-time data

Keep machines running, costs down, and efficiency up. Predictive maintenance, intelligent automation, and optimized workflows minimize downtime, reduce labor inefficiencies, and cut material waste. AI-powered insights fine-tune production, maximizing output while using fewer resources.

1 of 4

Our Manufacturing clients’ success stories

What are the types of software used in manufacturing?

How do you ensure your manufacturing software meets industry standards?

Can you integrate new manufacturing software with our existing ERP or legacy systems?

Is ongoing support and maintenance necessary for manufacturing software?

What advanced technologies do you incorporate into manufacturing software?

Haven’t you found the answers?

Talk to usAvailable for projects

Want to talk about your project?

Partner with us for a digital journey that transforms your business ideas into successful, cutting-edge solutions.