Industry 4.0 Software Development Services

Cut costs, improve scalability

Leverage tailored Industry 4.0 solutions in factory, warehouse or logistics centre for scalable growth, efficiency, and long-term sustainability.

Consult your idea

50%

cut order-to-production time with our tailored solutions

+30k

custom-configured products managed daily with our seamless solutions

0.5s

to synchronize order data between all legacy systems and the sales platform

Our expertise

Delivering innovative, scalable, and tailored Industry Tech solutions that empower manufacturing to thrive in a digital-first era.

Book free consultation

Workshops and needs analysis

Tailored solutions for Industry 4.0 optimization - pinpoint inefficiencies and uncover growth opportunities with targeted workshops that drive seamless digital transformation.

AI-powered assistance for B2B interactions

Boost customer support with an AI chatbot that automates inquiries, streamlines orders, and integrates with key systems for faster, more efficient interactions.

AI assistance for factory, warehouse and workforce efficiency

Optimize factory and warehouse operations with an AI-driven assistant that provides real-time guidance, automates workflows, and enhances productivity across teams.

Your Industry 4.0 advantage

Increase conversion rates

Miquido’s Industry 4.0 solutions improve product quality and ensure timely delivery, building customer trust. Real-time insights align production with demand, reducing delays and boosting sales conversions.

Reduce operational costs

By automating processes and enabling predictive maintenance, Miquido helps cut operational expenses. Optimized resource usage and reduced downtime lower costs while maintaining efficiency.

Enhance customer satisfaction

Miquido ensures transparency with real-time updates and faster complaint resolution. Consistent quality and reliable service improve customer trust and loyalty.

Improve decision-making

Ensure seamless access to critical data through integrated digital platforms. Modern sales support systems simplify order management, optimize pricing and provide actionable customer insights. These tools empower teams to make fast, informed decisions, boosting responsiveness and driving sales success.

1 of 4

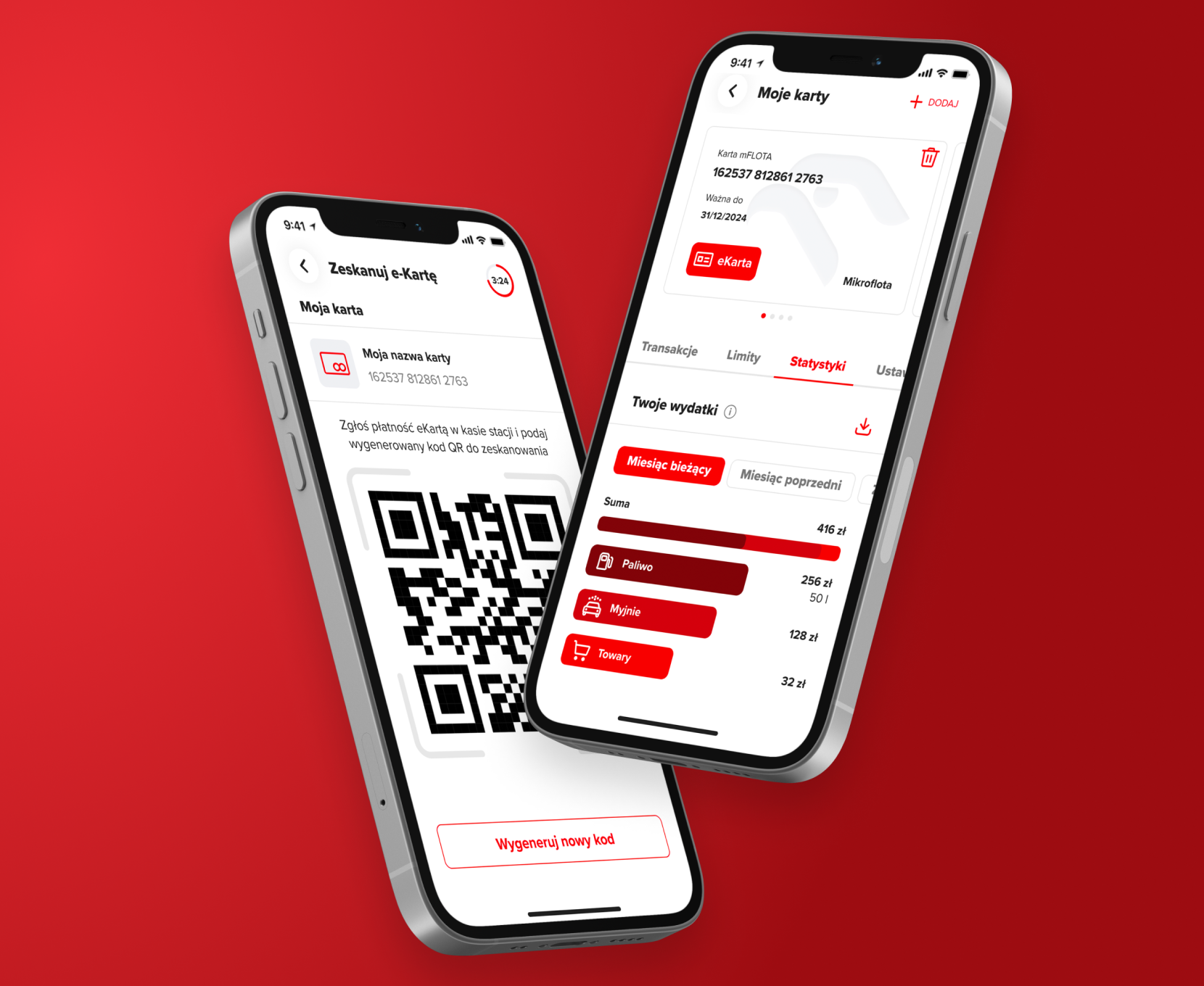

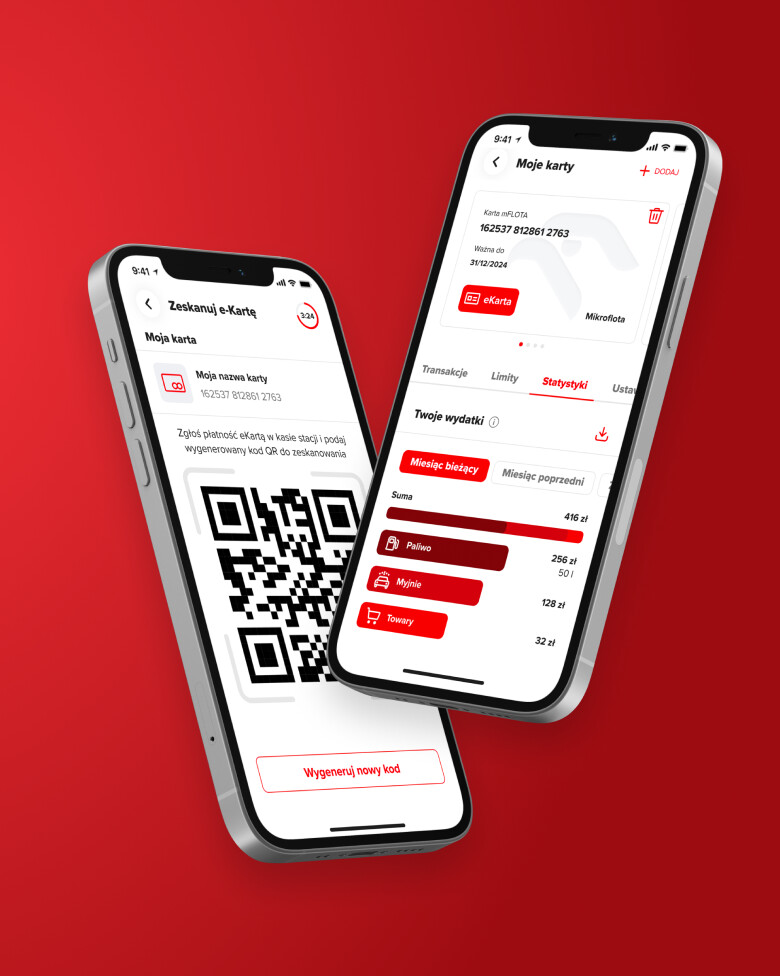

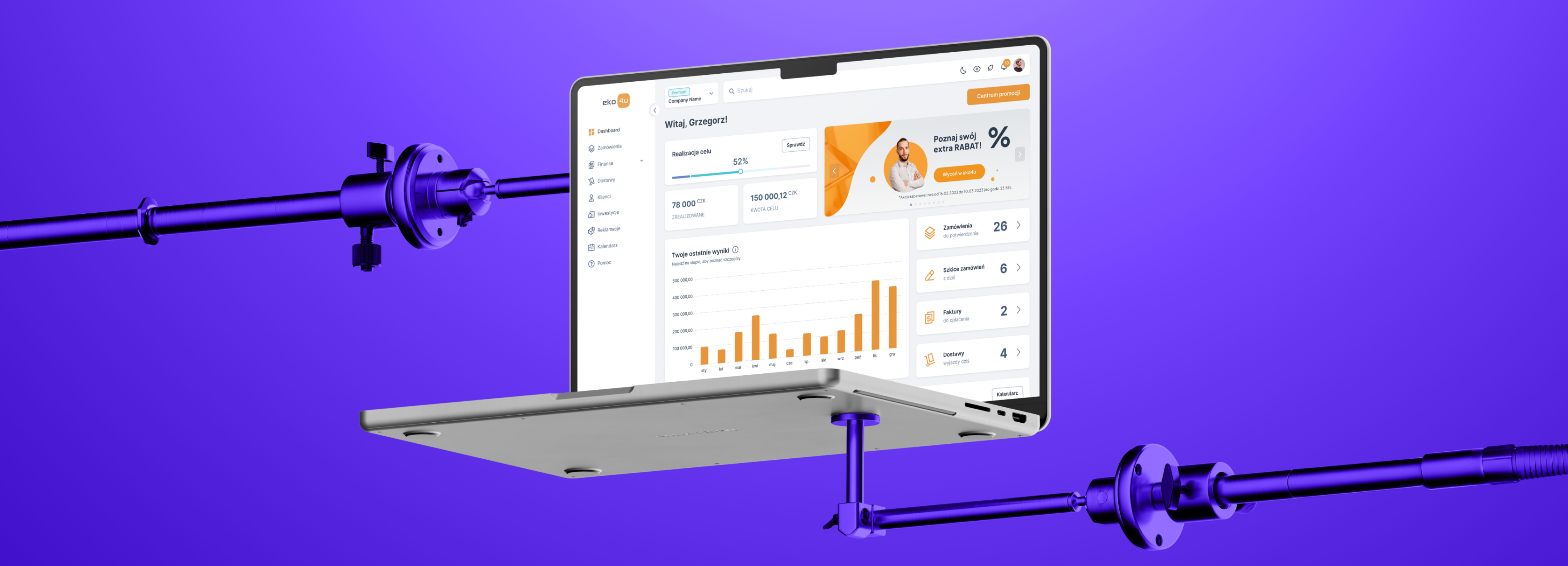

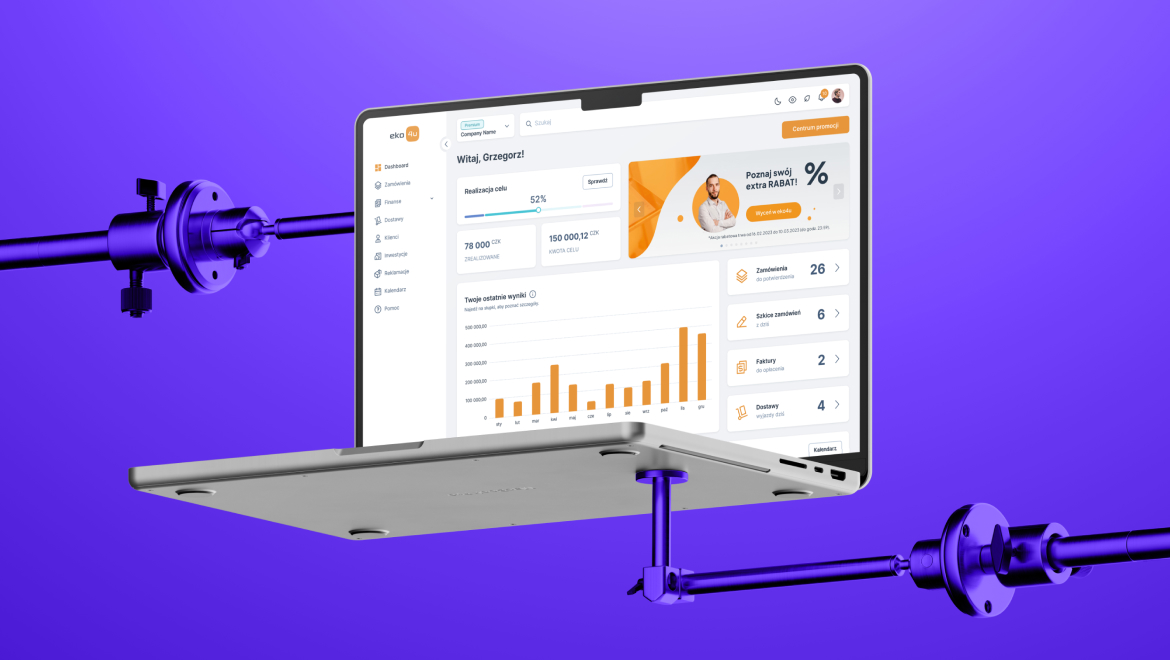

Our Industry 4.0 clients' success stories

What types of solutions do you offer for Industry 4.0 transformation?

How can your services address the challenges of transitioning from legacy systems to modern digital tools?

What industries or manufacturing sectors do you cater to within Industry 4.0?

How do your tailored solutions compare to off-the-shelf systems like APS, MES, or WMS?

What role does AI and machine learning play in your Industry 4.0 solutions?

What is your approach to ensuring a smooth implementation of Industry 4.0 projects?

Haven't you found the answers?

Talk to usAvailable for projects

Want to talk about your project?

Partner with us for a digital journey that transforms your business ideas into successful, cutting-edge solutions.