Manufacturing industry is changing in front of our eyes, drifting towards the Industry 4.0. This term, referring to a widespread and orchestrated digital transformation, encompasses a wide range of innovations, from ERP systems to e-commerce platform integration.

As the subcategory of manufacturing, joinery industry is absorbing digital transformation like a sponge. Its specifics make it a perfect fit for automation solutions, guaranteeing high success rate.

Our competitive analysis of the industrial sector assesses the current state of implementations and identifies key trends.

Industry 4.0 in joinery: digitization, automation, and smart solutions

Industry 4.0 is driving fundamental changes in manufacturing, pushing companies toward automation, digitization, and smart solutions. Given the level of detail and precision required, joinery businesses are increasingly investing in three key areas: digital management and design, production automation, and smart warehousing.

Many woodworking processes in joinery, such as cutting, shaping, drilling, and assembly, are highly repetitive and require extreme accuracy. AI-powered CNC machines and robotic arms can handle these tasks more efficiently than humans, ensuring consistent quality and precision.

Take, for example, a custom window —its journey usually begins in a configurator, then it passes through various design tools to finally reach the assembly line. On each stage, AI and other Industry 4.0 solutions can reduce human error, minimize material waste, and accelerate production cycles.

Once the joinery product is ready, its automated journey doesn’t end. Industry 4.0 tools ensure that storage, tracking, and logistics are handled with the same level of efficiency as production, covering storage and retrieval systems, RFID and IoT Tracking and logistics.

Who’s investing in R&D for smart manufacturing?

Smart manufacturing solutions often take time to gain visibility due to extensive implementation period. But don’t be deceived – joinery companies in Europe are betting on production automation, as the example of these internationally growing brands show:

- Erkado is investing 145 million PLN in an R&D center and an automated warehouse. While technological investments can boost efficiency, their practical application is crucial.

- Sonarol has focused on optimizing gaskets—a seemingly minor adjustment that can have a significant impact on large-scale production.

Warehouse automation: A game changer

With these advanced tools, joinery businesses can ensure just-in-time deliveries, reduced storage costs, and seamless integration with e-commerce and distribution channels. By embracing smart warehousing, companies enhance efficiency, minimize errors, and improve customer satisfaction—solidifying their competitive edge in the digital age.

These benefits are becoming increasingly visible for the manufacturing companies in Europe and globally. And they are ready to think big! For instance, Oknoplast, one of the five largest manufacturers of windows in Europe with presence in 10 countries, is investing in a fully automated high-bay warehouse, which could significantly shorten order fulfillment times and reduce operational costs.

Results speak for themselves – based on examples of Oknoplast or Fakro, companies integrating digitization with warehouse automation and high performance machining gain a competitive advantage in order fulfillment speed.

B2B eCommerce and product configurators in woodworking

Currently, 49% of B2B spending occurs online, and this figure is expected to rise to 57% in the next five years. Businesses that fail to adapt risk losing their market relevance.

Online platforms are becoming a standard in woodworking industry, driving profit from B2B customers. Advanced and targeted features can make a manufacturer stand out. On the other hand, the lack of modernized B2B e-commerce platform is often a primary reason for the client to migrate to another partner.

Although manufacturing is one of more traditional industries, the B2B customers are clearly looking for modern tools. Take an example of Polish joinery manufacturer – Dobroplast. The company reported a growing number of orders completed entirely online. In 2022, the company recorded dozens of purchases made 100% digitally, without a sales representative’s involvement.

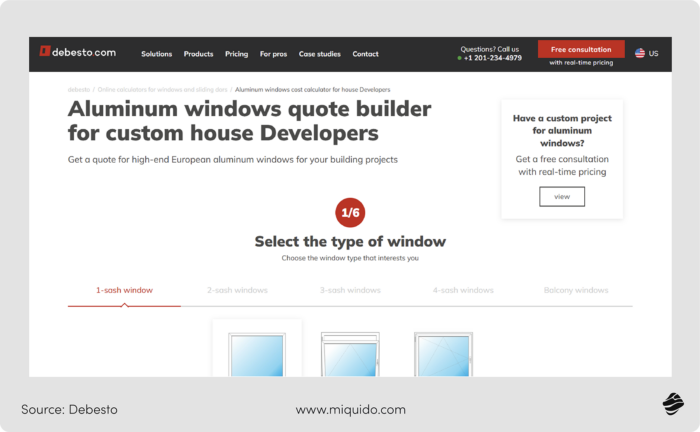

While most manufacturers decide to use online platforms as support, some completely revolutionize their approach to sales. Another international company with links to Poland, Debesto, has moved its brokerage model online, achieving a turnover of 5–10 million PLN.

Companies like Drutex and Portos TR7 have implemented B2B platforms, but their success depends on refining customer service to ensure that modern solutions genuinely improve sales processes.

A “Mystery Shopper” study in Austria revealed that only 1/3 of industrial sellers responded to customer inquiries within 24 hours. This highlights that while e-commerce is crucial, it must be backed by excellent customer service to drive success. Here too, automation is the answer. Automating your shop customer service area with chatbots and knowledge bases can be a gamechanger, leaving your clients less frustrated and more informed.

How configurators improve sales and customer experience

Configurators simplify product selection and customization, but they do not always lead to quick purchasing decisions. A well-designed configurator with high usability is the key to success.

Germany’s digital buying trend shows that 90% of buyers use the Internet for research, yet many suppliers fail to make their platforms intuitive. The configurator feature, if well-designed and user-friendly, is a powerful tool to convince undecided clients to make a purchase—they can see the effect firsthand from every angle.

Integrating modern technologies can further improve the user experience, leading to better sales and higher cart value. For instance, Eko-Okna’s configurator uses AR technology to enhance the customer experience.

AR and GenAI in woodworking industry eCommerce solutions

By allowing customers to visualize products in their real environment, AR reduces uncertainty and increases purchase confidence. This immersive experience encourages higher-value purchases and lowers the likelihood of returns.

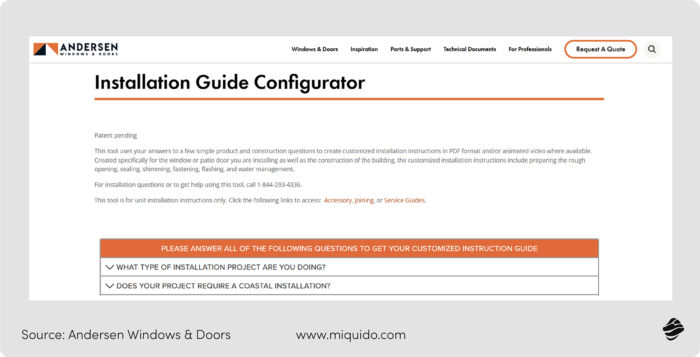

With GenAI, leveraging configurator features is easier than ever. Woodworking companies also notice value in customer education, which can reduce return rate and enhance loyalty, especially if paired with personalization.

For instance, Andersen Windows & Doors offers instructional configurators that automatically generate personalized installation videos—enhancing the entire value chain, from manufacturing to customer support. Such solution reduces demand for customer support and provides direct access to information in advance, making the client feel taken care of.

Sustainability and smart solutions in Industry 4.0

Industry 4.0 facilitates reduction of emissions across the whole manufacturing supply chain, enabling companies to track their carbon footprint on every stage of the process. In the EU, the regulations are putting an increasing pressure on woodworking companies, requiring detailed reporting, which can be automatized with digitalized solutions. Environmental certifications such as EPD (Environmental Product Declaration) are becoming standard, giving companies a competitive edge in the market.

Companies in the sector are further optimizing production by automating their woodworking processes. The benefits of automating include greater efficiency, lower waste, and improved product consistency, especially with woodworking machines featuring CNCs for precision control.

The growing market for eco-friendly products

As companies face growing pressure to go green, market trends indicate that the green transition can also boost profitability. The demand for eco-friendly products is solidifying as customer habits evolve. While cost savings on heating and cooling remain a primary concern, sustainability is becoming increasingly important to consumers.

The rising popularity of eco-friendly pergolas is a prime example. Leaders in the woodworking industry have quickly adapted to this trend—Aliplast, for instance, is launching bioclimatic pergolas, while Portos TR7 has reported a 25.4% profitability increase in this category. Fakro is also prioritizing energy-efficient technologies, such as the ThermoPro system and anti-burglary solutions that enhance window durability.

Government programs further fuel eco-friendly trends, often resulting in radical sales spikes. For instance, Italy has introduced a subsidy program that reimburses 100% of the costs for sustainable installations. This policy has driven a 9.7% increase in awning sales and a 25.4% growth in pergola sales.

Best practices in industrial automation

Transition to industry 4.0 in joinery and other manufacturing niches has to be planned thoroughly to bring long term, substantial results. It may take some time – but it is worth it! Take a look at Dobroplast. The company spent a year preparing for digitization by analyzing its processes and eliminating inefficiencies—demonstrating the importance of thorough planning.

Analyzing the competition and learning from these insights is an important step. Before automating your woodworking processes, you can see which steps the other market leaders took and what were the results. We gathered case studies from the Polish woodworking market to show you the current state of innovation in the industry. Although the ranking is market-specific, many of these companies have a broad international presence, impacting and absorbing global trends.

Case studies: leading companies in woodworking automation

| Company | Description |

|---|---|

| Dobroplast | Preparing for digitization and implementing order management solutions. Increased online sales despite a 5% revenue decline. |

| Debesto | B2B platform with projected revenues of 5–10 million PLN. Configurator for gate parameters improves pricing accuracy. |

| Drutex | Strong digitalization efforts but faces UX challenges in configurators. |

| Droma | New IT systems enhance planning, cost control, and financial management. |

| Oknoplast | Offers B2B and B2C configurators, intelligent invoice processing, and an online claims system. |

| Fakro | Uses AR/VR for interactive product presentations, boosting roof window sales. |

| Wikęd | iQuote order management system increased sales by 11.93% to 341.4 million PLN in 2022. |

| Winkhaus | Multi-language B2B configurator and mobile app for installers and dealers. |

| Erkado | R&D investments and automation led to a 9.87% revenue increase to 373.9 million PLN. |

Based on these market insights, without a doubt:

- B2B e-commerce will become the standard – Companies that fail to adapt will lose competitiveness.

- Automation must have practical benefits – Investments in new technologies should enhance efficiency, not just add complexity.

- Sustainability and cost-efficiency go hand in hand – Businesses must implement solutions that generate real savings.

- Customer expectations are evolving – Awareness of sustainability and online service quality will drive future purchasing decisions.

Monitor the joinery market with an experienced partner

Digitization, automation, and sustainability are shaping its future. The key question remains: Which companies are truly innovating, and which are merely following trends?

Monitoring the competition is vital to informed business decisions, especially when implementing woodworking automation solutions. However, it is hard to do that on your own.

We can help you find the answer with our market research services. Our experts will prepare a comprehensive analysis, providing you with the big picture and actionable insights.

![[header] woodworking automation – how joinery industry is growing with digital transformation which is right for your project](https://www.miquido.com/wp-content/uploads/2025/03/header-woodworking-automation-–-how-joinery-industry-is-growing-with-digital-transformation-which-is-right-for-your-project.jpg)

![[header] case study b2b system development and product configurator implementation

in industry 4.0](https://www.miquido.com/wp-content/uploads/2025/04/header-case-study_-b2b-system-development-and-product-configurator-implementation

in-industry-4.0-432x288.jpg)

![[header] exploring the key benefits of ai in manufacturing industry](https://www.miquido.com/wp-content/uploads/2025/04/header-exploring-the-key-benefits-of-ai-in-manufacturing-industry-432x288.jpg)

![[header] woodworking automation – how joinery industry is growing with digital transformation which is right for your project](https://www.miquido.com/wp-content/uploads/2025/03/header-woodworking-automation-–-how-joinery-industry-is-growing-with-digital-transformation-which-is-right-for-your-project-432x288.jpg)